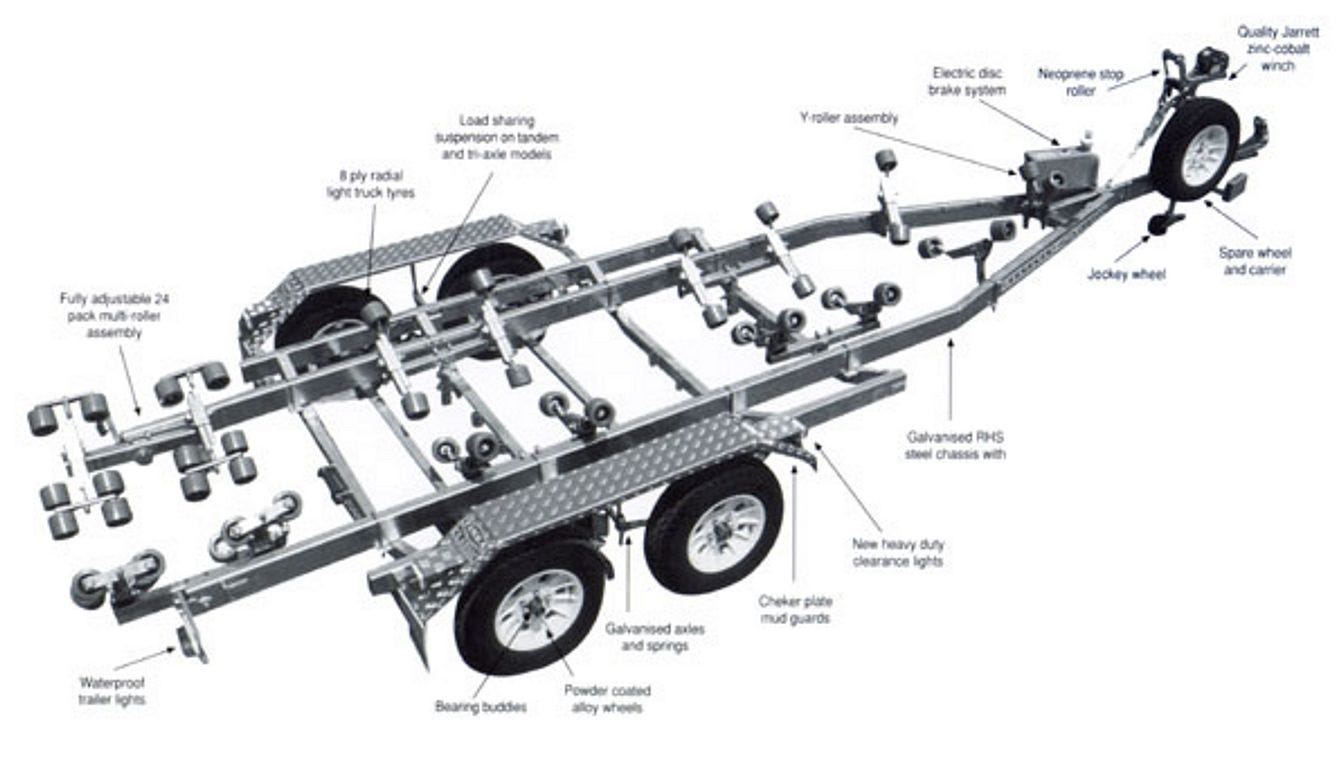

We would recommend treating the drilled area with a corrosion preventive product. This position varies for each trailer manufacturer. What makes them universal is that the customer will have to drill holes in the tube for the spring seat position exactly as it is on the axle being replaced. The 3500 lb axles will also be available up to 96” overall length with a standard 1-3/8” x 1-1/16” spindle with brake flange. These 2” x 2” axles will be supplied by Tie Down Engineering and be available in 2000 lb rating (up to 96 inch overall length) with a 1-1/16” straight spindle. It a few weeks we will be offering a new product line that will be of interest to owners of older boat trailers… the galvanized square tube universal axle. If you have an EZ Loader trailer, select EZ-LOADER Factory Trailer Parts. If you have a Load Rite trailer then select LOADRITE Factory Trailer Parts. Just about any part you need is available including axles, leaf springs, brakes, winch post parts, etc. Aluminum is also frequently used as a material.Įastern Marine specializes in replacement parts for boat trailers. Zinc electro-plating will help but due to the plating porosity, corrosion will gradually erode the part. The traditional method to help retard corrosion in boat trailer components is to galvanize using hot dip zinc.

Finding parts for specific brands of boat trailer is not easy because many manufacturers have closed their operations years ago.

If this happens, the part will need to be replaced. Rust starts on the surface but if not corrected, will corrode the part until it fails. With steel as the metal, iron oxides are the compounds that form rust (Fe2O3/FeOOH). A definition of corrosion is “development of metal oxides on the surface of a metal part”. Boat Trailers are different from other types of trailers and RVs because they get immersed in water (often salt water) and that accelerates corrosion or rust.

0 kommentar(er)

0 kommentar(er)